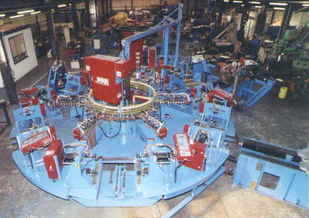

Gravity Diecasting Equipment

WORSWICK manufacture a range of gravity diecasting machines, from single station machines for the production of small parts, up to large rotary multi-station carousel type machines with automatic metal feed, automatic casting extraction and quick die change facilities.

The majority of applications are for the mass production of automotive parts for instance, brake cylinders, engine mountings, thermostat housings, cylinder heads, engine blocks, road wheels and gearbox casings etc. In all cases, the die operation is by hydraulic cylinders, totally relieving the operator of the task of opening and closing the die parts. The control of the die opening and closing is either by means of a mechanical cam system on the simpler smaller machines, or by individual PLC’s on each die, which are networked into a central control PLC on the larger machines.

| SINGLE STATION MACHINE  | 6 STATION MACHINE  |