Stacking Machines

ADVANCED AUTOMATED STACKING SOLUTIONS FOR NON-FERROUS INGOTS AND SLABS

WORSWICK designs and manufactures a comprehensive range of high-performance ingot and slab stacking systems engineered for aluminium, zinc, lead, silver, and magnesium alloys. Each solution is tailored to material type, casting layout, stack geometry, and production throughput. Our portfolio includes the following advanced systems:

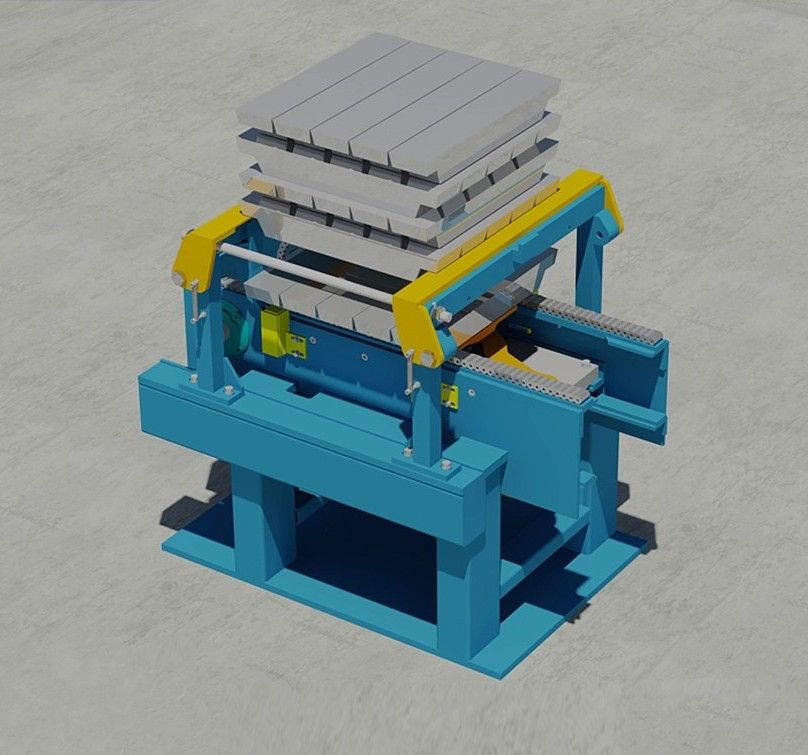

1. Lift Table Ingot Stacking System

The Worswick Lift Table Stacker is specifically engineered for high-speed stacking of aluminium, zinc, and magnesium ingots in the 5–15 kg range. This system significantly outperforms radial arm stackers in terms of throughput, achieving stacking rates of up to 2,200 ingots/hour, subject to ingot dimensions and stack layer configuration.

Key features include:

-

Optimised for regularly shaped ingots where the total width of the layer is less than the ingot length.

-

Two-axis conveyor design:

-

Ingot Receiving Conveyor: Incorporates a selective turnover unit.

-

Lift Table Stacking Conveyor: Positioned at 90° to the receiving conveyor, feeds into a walking beam-type stack storage conveyor (with capacity for 5+ stacks).

-

-

Customisable layout options: left-hand, right-hand, or inline conveyor configurations.

Heavy-Duty Variant:

Capable of stacking ‘eared’ pigs/ingots in the 15–50 kg range, with options for nested or non-nested, cross-layered configurations. Stack weights between 1.0 and 2.0 tonnes are achievable, with stable formations suitable for automated strapping or forklift handling.

2. Radial Arm Ingot Stacking System

Designed to stack complex ingot geometries—including eared, interlocking, and T-shaped formats—ranging from 450 mm to 840 mm in length. The Radial Arm Stacker offers flexible ingot orientation and positioning, accommodating intricate stacking requirements:

System capabilities:

-

Orientation modes:

-

Same-direction stacking

-

Alternating turnover or end-for-end interlocking

-

-

Special configurations for forklift foot positioning or intentional void creation

-

Stack geometry options:

-

90° alternating cross-layers

-

Parallel orientation

-

Combination patterns

-

-

Throughput capacity: over 1,000 ingots/hour, depending on layer density and layout.

-

Modular design allows seamless integration into existing casting lines or constrained plant layouts.

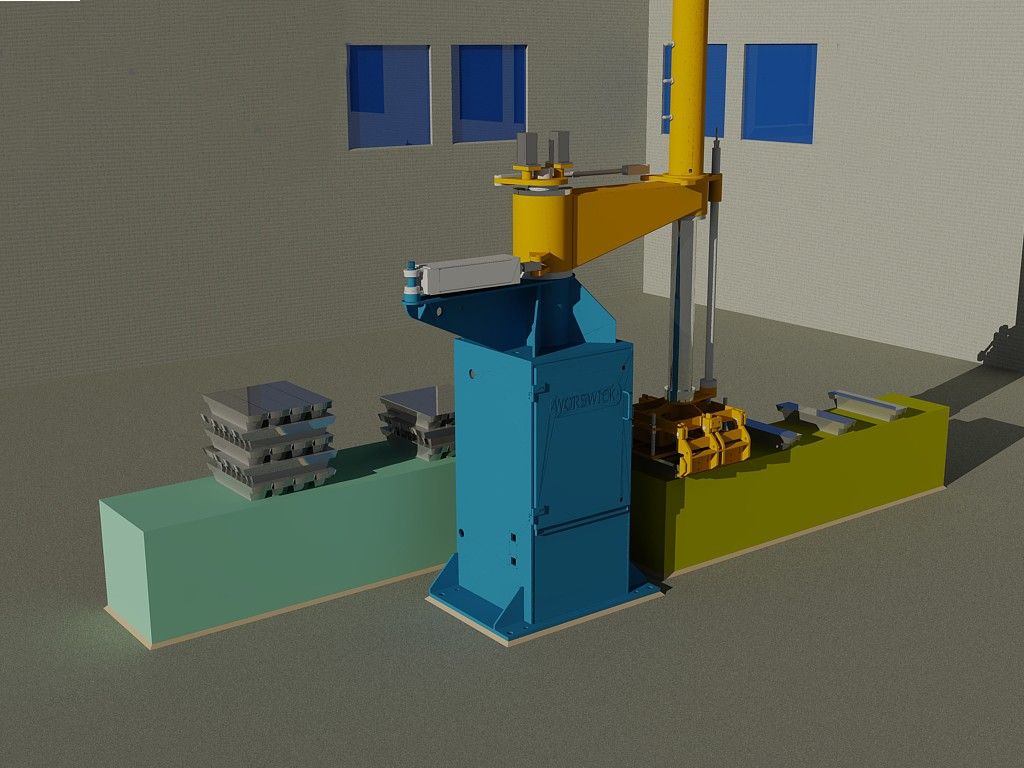

3. Gantry-Type Ingot Stacking System

The Gantry Stacker is the most versatile and fully automated solution in the Worswick stacking range. Suitable for a broad variety of casting machine interfaces—inline or rotary—this system is highly configurable and engineered for demanding stacking operations.

Comprises three main subsystems:

-

Ingot Receiving Conveyor

-

Chain-type with optional ingot turnover and oversize/undersize rejection modules.

-

-

Overhead Gantry System

-

High-speed servo-driven carriage with precision ingot gripping head.

-

-

Multi-Position Stack Storage Conveyor

-

Twin-chain, chain-and-slat, or chain-and-stillage configuration (based on stack/pallet style).

-

Stacking Capabilities:

-

Builds nested or cross-layered square stacks on:

-

Wooden pallets

-

Precast bases

-

Regular foot ingots

-

-

Double-stack configuration on shared base available (bonded or separated).

-

Throughput: up to 1,800 ingots/hour.

Additional Options:

-

Hot stacking compatibility (onto steel or concrete bases).

-

Integration with Worswick Cooling Conveyors for pre-stack heat management.

4. Zinc Slab Stacking System

This specialised system complements Worswick’s automated zinc casting lines and is designed for stacking primary Zn slabs and pedestal foot ingots.

Available Models:

-

Single-Head Version:

-

Up to 500 slabs/hour (~12.5 t/h at 25 kg per slab)

-

-

Twin-Head Version:

-

Up to 1,000 slabs/hour (~25 t/h at 25 kg per slab)

-

Core features:

-

Seamless integration with Worswick casting equipment or third-party machines via custom interface conveyors.

-

Stack configuration options include:

-

Slab-only stacks

-

Slab/pedestal foot ingot combinations

-

-

Programmable turnover system for monogram orientation (face-up or face-down).

-

PLC-driven logic allows rapid format switching and stack program changes.

System Composition:

-

Ingot receiving conveyor with slab straightening and turnover unit

-

Pneumatic or servo-powered stacking actuator

-

Multi-position storage conveyor (up to 5 stacks; expandable)